What Safety Standards Should Be Followed When Building an Obstacle Course

Core Safety Standards: Understanding ASTM F1487 and EN 1176 for Obstacle Courses

The Role of ASTM International in Developing Safety Guidelines for Obstacle Course Design

The organization known as ASTM International sets important safety standards for how obstacle courses should be built, using input from various experts in the field. Their standard called ASTM F1487 covers things like how strong structures need to be, what materials can last over time, and special areas around equipment where kids might fall. A recent look at the 2025 edition of the CPSC Safety Handbook shows something interesting - most cities across America, probably around 8 out of 10, are actually looking at these ASTM rules before they give the green light for commercial obstacle courses. What makes these standards so valuable is that they test whether equipment can handle regular wear and tear without breaking down. They also make sure there aren't any places where small body parts could get stuck or caught on sharp edges and corners during play.

How EN 1176 Applies to Children’s Obstacle Courses in Public and Private Spaces

The EN 1176 standard from Europe sets out safety rules for playground equipment across various locations like schools, parks, and even residential areas. The guidelines insist on having shock absorbing surfaces under climbing structures and limit how wide gaps can be between different levels to stop kids from getting their heads stuck. This is different from the ASTM F1487 standard which only covers public playgrounds. When looking at real world applications, compliance matters a lot. According to a recent 2023 safety check conducted by the EU, places following these standards saw about 42 percent fewer cuts and scrapes than those without proper certification. Makes sense why so many facility managers prioritize meeting these requirements nowadays.

Key Differences Between ASTM F1487 and EN 1176 in Safety Scope and Enforcement

Both ASTM F1487 and EN 1176 deal with preventing falls and ensuring structures stay stable, but they approach things differently. The ASTM standard mainly looks at equipment used by the public for certain age ranges, while EN 1176 applies to a wider range of situations including those backyard setups many people install themselves. When it comes to enforcement, ASTM guidelines get incorporated into local building regulations depending on where someone lives. On the other hand, EN requirements must be followed everywhere within the European Union. These differences matter quite a bit, which is why we've put together a quick comparison table right here to make everything clearer.

| Criteria | ASTM F1487 | EN 1176 |

|---|---|---|

| Enforcement Mechanism | Voluntary adoption | Legal requirement |

| Age Range Coverage | 2–12 years | All pediatric users |

| Surfacing Depth Requirements | Varies by fall height | Minimum 12 inches |

This regulatory landscape requires designers to choose standards based on target markets and jurisdictional requirements.

Fall Protection and Impact-Absorbing Surfacing Requirements for Obstacle Courses

Recommended Impact-Absorbing Surfacing Materials to Reduce Injury Risk

The industry has set requirements for impact absorbing surfaces in obstacle courses, typically using materials such as rubber tiles, engineered wood fiber, or poured in place urethane products. According to ASTM F1292 guidelines, these surfaces need proper lab testing to determine their fall height rating. This rating basically measures how well a surface can reduce those sudden stopping forces when someone falls onto it, ideally keeping them under 200g force levels. A recent study from the Playground Safety Institute showed pretty impressive results too. Their 2025 research indicated that playgrounds with compliant surfaces saw about 58 percent fewer serious head injuries than those without proper surfacing. That kind of statistic really highlights why following these safety standards matters so much for children's play areas.

Calculating Minimum Fall Zone Requirements Based on Obstacle Height and Usage

When setting up fall zones, they need to stretch out about six feet past whatever obstacles are around, and the depth needs to match certain ratios too. For instance, if something stands six feet high, there should be roughly nine inches of stuff like wood chips or sand underneath it. The ASTM F1487 standard has what people call the "six inch rule," basically saying add six inches of padding material for each foot the equipment rises off the ground. Looking at recent studies, solid surfaces such as rubber mats can handle falls from heights up to eight feet without issues, but those loose materials we mentioned earlier work best when dealing with structures less than seven feet tall. Safety experts often recommend checking local regulations since requirements can vary depending on location and specific playground setup.

Case Study: Reducing Pediatric Injuries Through Compliant Surfacing in Playground Obstacle Courses

A 2025 analysis of 12 community playgrounds demonstrated a 47% reduction in concussion rates after upgrading to ASTM-compliant rubber mulch surfaces. Arm fractures decreased by 33% in the same cohort, validating the correlation between proper surfacing depth (maintained at 12 inches) and injury prevention in high-traffic obstacle courses.

Structural Integrity and User-Focused Design: Edges, Surfaces, and Ergonomics

Engineering Standards for Structural Integrity to Prevent Collapse or Failure

When building obstacle courses, engineers need to follow solid construction guidelines so these structures can hold up against all sorts of forces when people jump, climb, and run across them. Most designs actually need to handle about three to five times what someone would normally weigh, and those important connection points get put through rigorous testing to see if they can take repeated strain without breaking down. According to research published last year looking at adventure gyms around the country, facilities that stuck to the ASTM F2291-22 durability standards saw almost four out of five potential breakdowns prevented compared to older setups over five years. This kind of attention to detail really makes a difference in keeping both participants safe and equipment functional longer term.

- Galvanized steel frames with corrosion-resistant coatings

- Composite materials with tensile strengths exceeding 50,000 psi

- Redundant load paths in elevated platforms and climbing structures

Importance of Rounded Edges and Non-Slip Surfaces in Minimizing Lacerations and Falls

Rounded edges (minimum 0.12" radius) and textured surfaces reduce injury rates by 42% in obstacle courses, according to CPSC (Consumer Product Safety Commission) 2023 data. Non-slip surfaces with a static coefficient of friction ≥0.6 are critical on:

| Surface Type | Recommended Material | Slip Resistance Rating |

|---|---|---|

| Horizontal | Thermoplastic rubber | 0.68 |

| Vertical | Glass-reinforced polymer | 0.63 |

These design elements prevent hand slippage during climbs and minimize impact forces during falls.

Trend Analysis: Adoption of Ergonomic and Injury-Preventive Design Features in Modern Obstacle Courses

New equipment designs are starting to include those ergonomic grips with angles between 30 and 45 degrees, which actually cuts down on wrist strain quite a bit - around 27% less than those old school 90 degree setups we used to see everywhere. Fitness centers have noticed this trend towards more user friendly obstacles coincides with fewer complaints about repetitive strain injuries too. Industry reports from last year showed a drop of about 34% in these kinds of problems across gyms nationwide. The latest modular obstacle courses come with adjustable settings so trainers can tweak the difficulty level on the fly without compromising safety standards. Some facilities even let members vote on what challenges they want next week, keeping things fresh while still meeting basic safety requirements.

Certification, Compliance, and Insurance: Legal and Operational Safeguards

Steps to Achieve Certification by Accredited Testing Agencies for Obstacle Course Safety

Obtaining certification begins with partnering with accredited agencies like the International Playground Equipment Manufacturers Association (IPEMA). A typical certification roadmap includes:

- Design documentation review covering structural calculations and material specifications

- Prototype testing under simulated load conditions (e.g., 1,000+ stress cycles per ASTM F1487)

-

On-site inspections verifying installation quality and fall zone compliance

Certification typically requires 6–12 weeks and reduces insurance premiums by 20–35% in comparative studies.

Legal and Regulatory Compliance: Navigating Liability, Insurance, and Local Codes

Public obstacle courses must reconcile three compliance layers:

- State/local building codes dictating egress routes and emergency access

- Disability access requirements under ADA Title III (2023 updates)

- Insurance minimums for liability coverage ($2M+ standard in municipal contracts)

Municipalities report 72% faster permitting for designs pre-approved by NRPA-certified consultants.

Insurance Requirements and Risk Assessment for Obstacle Courses

Comprehensive policies should cover:

- Third-party liability ($1M–$5M typical)

- Equipment failure with <48-hour emergency repair clauses

-

Participant waivers aligned with state tort reform statutes

A 2024 NRPA analysis shows 89% of claims stem from improper surfacing maintenance, emphasizing the need for $100k+ annual reserve budgets in high-traffic facilities.

Strategy: Implementing Routine Safety Audits and Incident Reporting Systems

Leading operators conduct:

- Weekly visual inspections of structural connections and surfacing integrity

- Quarterly ASTM F1292 impact testing using field-calibrated tripod penetrometers

-

Digital incident dashboards tracking near-misses and maintenance responses

This protocol reduces corrective action costs by 60% compared to reactive models, per 2023 PlaySafe industry benchmarks.

Balancing Challenge and Safety in Obstacle Course Racing (OCR)

Industry-Wide Safety Standards for Obstacle Course Racing Events

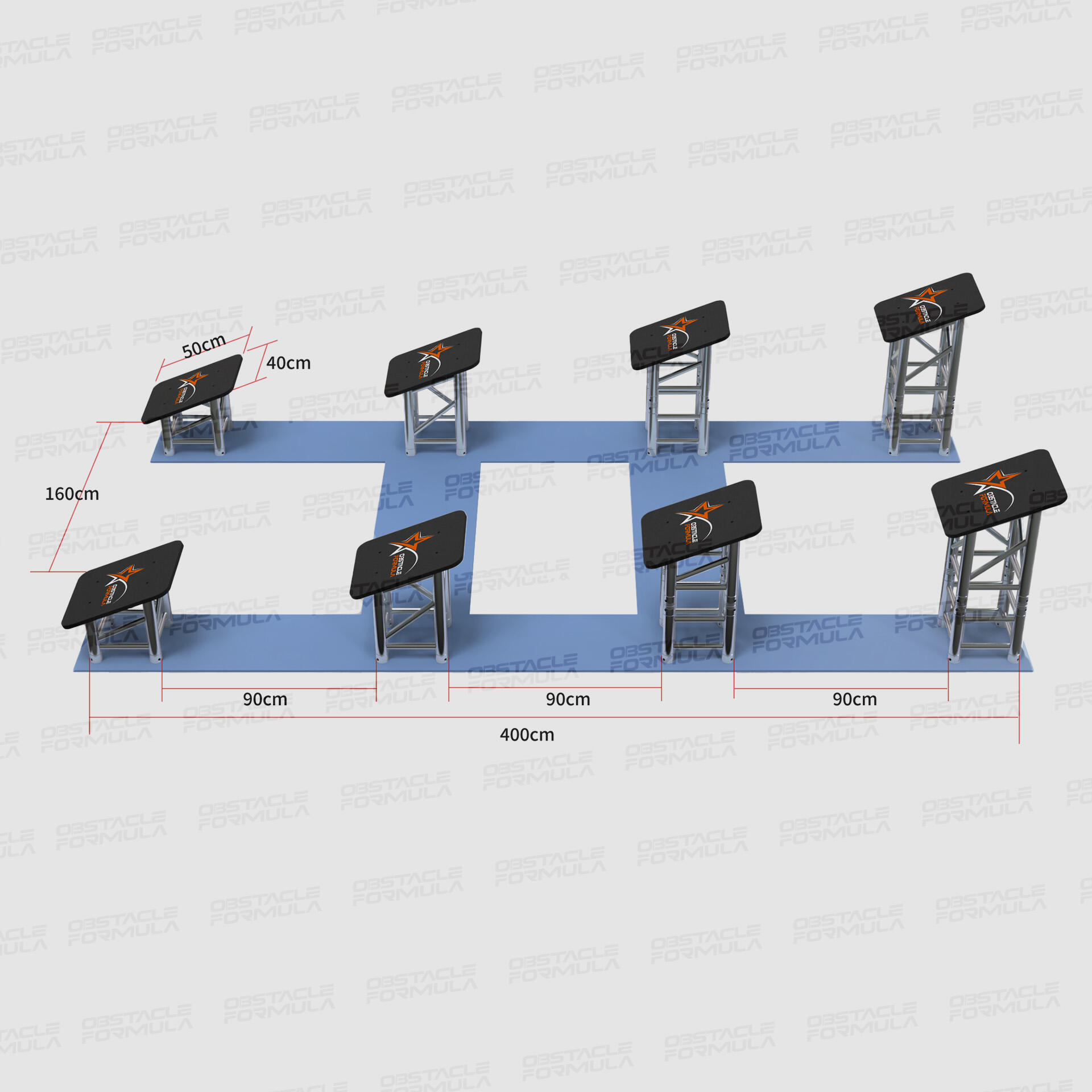

Safety comes first at obstacle course races, which follow strict guidelines based on ASTM F1487 and EN 1176 standards. These aren't just random numbers on paper either they actually set limits for how much weight different parts can handle, whether it's climbing walls, rope courses, or those high platforms people jump off. Anything taller than eight feet needs extra support structures in place so it won't fall apart when someone jumps or lands hard. Most event planners now get their courses certified by outside groups such as the International Obstacle Sports Federation. This gives both organizers and participants peace of mind knowing everything meets minimum safety requirements before anyone starts running through mud pits.

The Balance Between Risk and Safety in OCR Design: Athlete Experience vs. Injury Prevention

Designers have this tough balancing act going on between making obstacles that really test physical limits while also trying to prevent broken bones, cuts, and those nasty soft tissue injuries everyone hates. Looking back at some data from 2022 across about fifteen OCR events, roughly two thirds of all injuries happened at obstacles taller than six and a half feet high, mostly because people landed wrong after jumping down. These days we see things like slanted cargo nets that help slow folks down as they descend, plus safety talks before events where they explain how to tackle specific obstacles properly. Most courses now feature rounded corners, surfaces that won't let feet slip away, and padding in areas where impacts are likely. All these changes help cut down accidents but still keep the challenge intact for serious athletes who want to push themselves.

Trend: Growing Demand for Standardized Safety Protocols in Adventure Fitness Facilities

Most insurance companies these days require facilities to follow ASTM standards when it comes to covering liability for obstacle courses, which has pushed many businesses to get compliant across their entire operations. Looking at the numbers from the Adventure Fitness Market Report, we see that around 28 percent more facilities implemented ISO 9001 certified safety management systems from 2020 through 2023. Participants are clearly changing what they want too. According to a study released last year, roughly eight out of ten OCR athletes actually care more about how safe an event is than how tough the obstacles might be based on their feedback after events.